How does the operational longevity of a Permanent Magnet Synchronous Motor (PMSM) compare to traditional marine propulsion units? This examination focuses on the structural and operational factors that influence service life in demanding marine environments. The architectural differences between these systems lead to distinct durability and maintenance profiles. Santroll analyzes these factors in its design philosophy for marine-grade brushless motor systems.

Mechanical Wear and Component Longevity

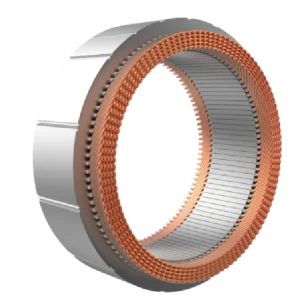

A primary differentiator is the presence of components subject to mechanical degradation. Traditional brushed electric motor designs incorporate physical brushes that transfer current to the rotor, a contact-based system that inevitably experiences wear. This continual friction necessitates periodic part replacement and maintenance. In contrast, the brushless motor architecture of a PMSM eliminates this sliding contact, removing a fundamental source of mechanical wear and contributing to a longer operational lifespan.

Environmental Resistance and System Integrity

The marine environment accelerates component degradation through moisture and corrosion. Both motor types require robust sealing, but the simplified internal structure of a PMSM often allows for more consistent and reliable environmental protection. The absence of brush dust and commutator arcing within a brushless motor also reduces internal contamination, helping to preserve the integrity of bearings and electrical insulation over extended periods.

Thermal and Electrical Stress Management

Heat is a primary factor in the aging of any electric motor. The high efficiency of a PMSM translates into less wasted energy as heat, resulting in lower operational temperatures. Reduced thermal stress on windings, magnets, and insulation materials slows the rate of performance degradation. This inherent efficiency of the brushless motor design supports sustained performance and contributes to an extended service interval.

The architectural advantages of PMSM technology directly influence its durability relative to traditional designs. The elimination of brush-based commutation reduces mechanical wear, while higher efficiency mitigates thermal degradation. For marine operators, this results in a propulsion system with a potentially longer service life and reduced maintenance frequency, offering a different value proposition based on total cost of ownership.