In an age where thermal management is crucial for optimal performance in numerous applications, liquid cooling systems have emerged as a preferred solution. The liquid cooling manifold plays a pivotal role in these systems, ensuring that coolant is distributed efficiently to various components. Understanding the importance of optimizing flow distribution within these manifolds can help businesses improve system efficiency, reliability, and longevity. Companies like Dingmetal are at the forefront, providing high-quality liquid cooling manifolds designed to meet diverse operational needs.

Defining the Liquid Cooling Manifold

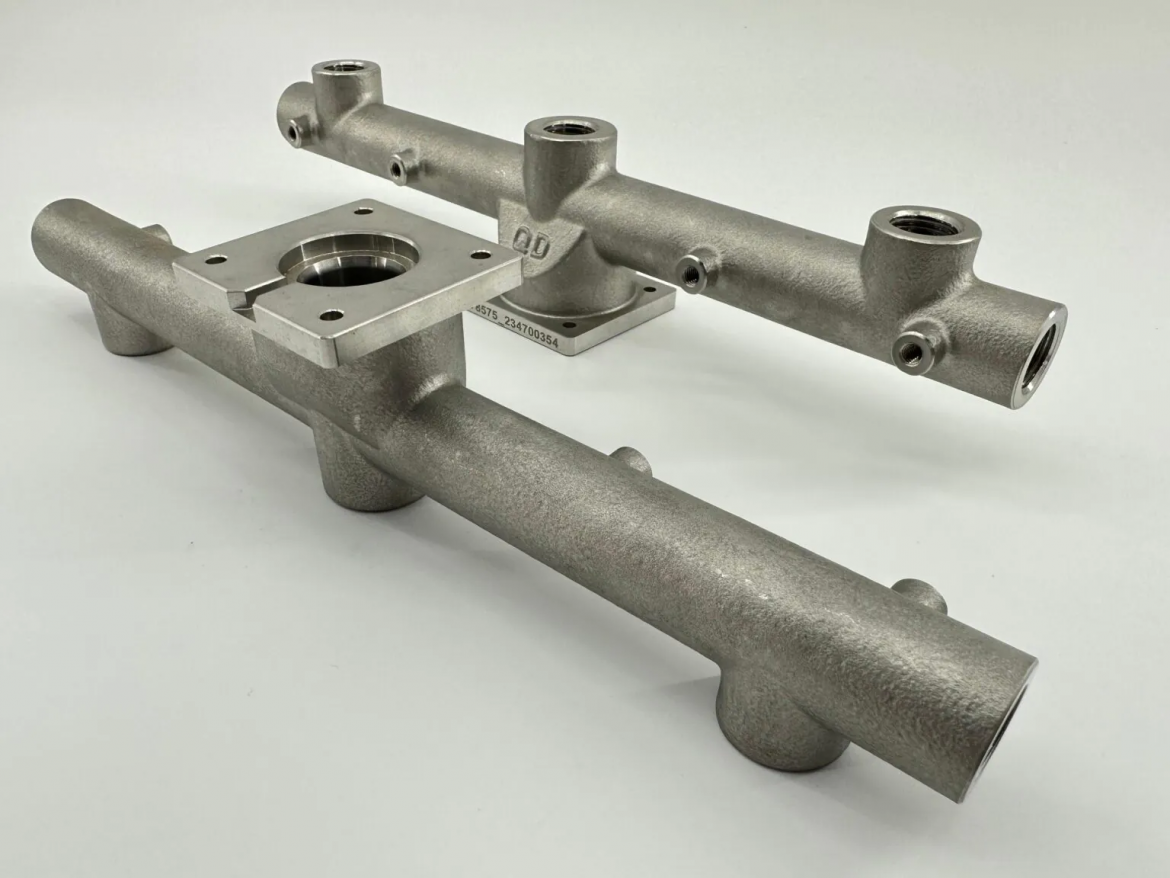

A liquid cooling manifold serves as a central hub in liquid cooling systems. Its primary function is to effectively distribute coolant to different pathways and components, ensuring that all areas receive adequate cooling. This is essential in preventing overheating and maintaining stable operational temperatures across systems, such as data centers, gaming computers, and automotive engines.

Dingmetal specializes in manufacturing a variety of liquid cooling manifolds, including intake and exhaust types, tailored to meet specific system requirements. By offering customized solutions, Dingmetal ensures that clients can find the right component to enhance their thermal management strategy.

Why Optimizing Flow Distribution Matters

Optimizing flow distribution within a liquid cooling manifold is critical for maximizing the efficiency of a cooling system. Poorly designed flow paths can result in uneven coolant distribution, leading to hot spots in certain areas while others remain inadequately cooled. This imbalance can significantly undermine the performance and lifespan of electronic components, ultimately resulting in costly failures and downtime.

Moreover, optimized flow distribution can minimize the risk of leaks within the system. Inefficient flow can create pressure imbalances, potentially leading to weak points in the manifold’s structure. With properly engineered flow distribution, such risks are greatly reduced, enhancing overall system integrity.

Dingmetal employs advanced engineering techniques to ensure optimal flow distribution in their liquid cooling manifolds. Through careful design and testing processes, the company delivers products that promote efficient and reliable thermal management, allowing businesses to operate with confidence.

Key Factors Influencing Effective Design

To achieve effective flow distribution in liquid cooling manifolds, several design factors must be considered:

1. Manifold Geometry: The shape and design of the manifold directly impact how coolant flows through the system. Streamlined designs that avoid sharp bends facilitate smoother flow, reducing turbulence and enhancing efficiency.

2. Material Selection: The choice of materials used in the construction of the liquid cooling manifold can affect both thermal conductivity and structural integrity. For instance, using aluminum or copper is often preferred due to their excellent heat transfer capabilities, ensuring efficient cooling performance.

3. Connection Architecture: Properly placed inlet and outlet connections play a vital role in balancing the flow of coolant. Thoughtful placement helps distribute coolant evenly to all components, preventing localized overheating and ensuring uniform temperature management.

By focusing on these critical design elements, Dingmetal ensures that their liquid cooling manifolds provide superior performance. Their expertise in developing customized solutions allows them to address the unique cooling needs of various industries.

Enhancing Performance Through Precision Engineering

For businesses operating in sectors that rely heavily on liquid cooling solutions, collaborating with an experienced manufacturer like Dingmetal is vital. Their commitment to precision engineering and tailored solutions empowers companies to achieve deeper insights into their thermal management approaches.

By investing in high-quality liquid cooling manifolds from Dingmetal, businesses can maximize performance, ensure efficient cooling, and position themselves for success in competitive markets. Ultimately, optimized flow distribution in liquid cooling manifolds stands as a cornerstone of effective thermal management, driving innovation and reliability in today’s demanding environments.