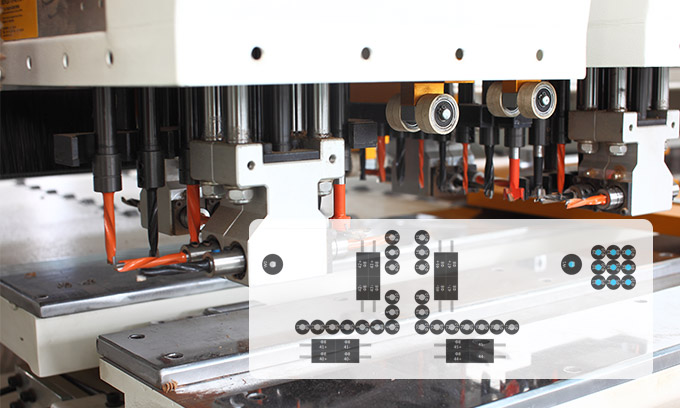

The CNC drilling machine should simplify complex workflows, and HUAHUA CNC’s SKH-612NS model, crafted in their 45,000㎡ Foshan facility, does exactly that. Part of a manufacturing series with consistent annual production, this CNC drilling machine combines advanced tech with intuitive design, making it accessible to operators of all skill levels.

Instant Startup with No Homing Hassle

Thanks to the Taiwan Syntec control system and servo motor, this CNC drilling machine skips the tedious homing process. Power it on, and it’s ready to work immediately—saving precious time during morning setups or quick job switches. The Syntec system’s stability ensures consistent performance even during long runs, while its global after-sales network means support is always within reach.

QR Code Scanning for Swift File Loading

Gone are the days of manual program input. The CNC drilling machine lets operators scan barcodes or QR codes to load processing files (MPR, DXF, BAN, XML) automatically, which then generate NC programs instantly. This cuts down on human error and speeds up transitions between custom orders, a boon for workshops handling diverse projects.

Intuitive Interface for Seamless Operation

The system’s visual interface is designed for clarity, with straightforward parameters and simple navigation. Even new operators can master the CNC drilling machine in hours, reducing training time. It also supports multiple data formats, integrating smoothly with popular design software to fit effortlessly into existing workflows.

Conclusion

HUAHUA CNC’s CNC drilling machine stands out for its user-centric design, from instant startup to QR code loading. It makes advanced drilling accessible, perfect for manufacturers seeking efficiency without steep learning curves.